Vaughan Company has a long history of innovation and quality. Jim Vaughan, the founder of Vaughan Company, invented the world's first chopper pump in 1960. The business started in the garage of Jim's gas station in Elma, Washington. Jim repaired the local dairymen's manure pumps, which experienced constant maintenance problems caused by clogging on bedding and twine. After spending many a wasted hour repairing pumps, Jim developed a unique design that effectively became the original chopper pump. Immediately, Jim realized he had invented something worthy of a patent.

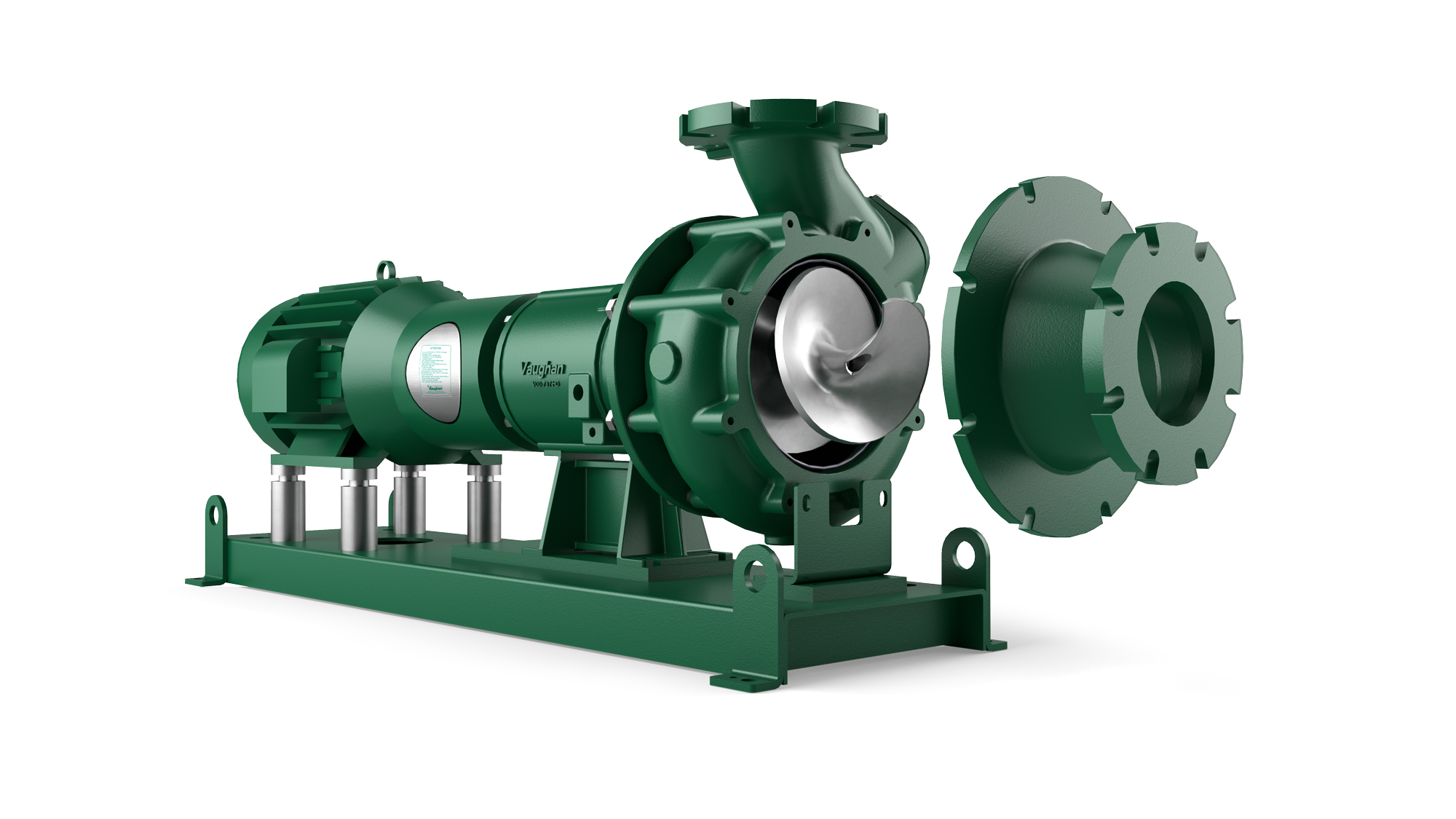

The Vaughan Chopper Pump is a centrifugal pump with the unique ability of chopping all incoming solids prior to pumping. This not only protects the pump from clogging, but also provides added benefit to downstream components, processes, and the environment.

All wear components are cast steel and heat treated for maximum impact and wear resistance. Combined together, these heavy duty patented components create the ultimate pump for handling severe solids.

This same basic concept has been used in Vaughan's vertical wet well design for almost a half-century.

Chopping is accomplished by the scissor action of the leading edges of the impeller vanes cutting against the opposing edges of the cutter bar.

All solids are chopped as they enter between the cutter bar and the impeller vanes. The smaller solids are easily pumped by the centrifugal action of the impeller.

The Rotamix system uses fixed nozzle assemblies. Once the nozzle assembly is installed, the nozzles are adjusted to the factory specified angle, and permanently tightened. No additional adjustment is required. Vaughan's chopper pump is the heart of the Rotamix system. Vaughan’s proven technology over the past 45 years provides long-term low maintenance, and the highest reliability of any chopper pump. Continuously chopped solids not only eliminate nozzle clogging, but enhance sludge quality. Digester efficiency is increased by further reducing solids size and increasing surface contact.

The Vaughan Chopper Pump is a centrifugal pump with the unique ability of chopping all incoming solids prior to pumping. This not only protects the pump from clogging, but also provides added benefit to downstream components, processes, and the environment. Chopper Pump configurations - horizontal dry well, pedestal dry well, vertical wet well, electric submersible, hydraulic submersible

The only self-priming chopper pump in the world! Simplify your set-up and reduce your maintenance costs with the Vaughan Self-Primer Chopper Pump. These pumps are designed to handle the toughest solids, while providing a cost-effective maintenance alternative to wet-pit pump installations. Self-primer pumps bring the same Vaughan Non-Clog Performance Guarantee to a maintenance-friendly chopper pump design.

Vaughan's Rotamix® system is the world's most reliable cost effective means of mechanical hydraulic mixing for sludge tanks, digesters and other high-volume applications. The Rotamix system incorporates several basic principles of physics and hydraulics, including uniform and vortical fields of flow, induced flow and surface contact. Combined together, this unique mixing system optimizes solids contact due to the homogeneous state. The Rotamix system uses fixed nozzle assemblies. Once the nozzle assembly is installed, the nozzles are adjusted to the factory specified angle, and permanently tightened. No additional adjustment is required. Vaughan's chopper pump is the heart of the Rotamix system. Vaughan’s proven technology since 1960 provides long-term low maintenance, and the highest reliability of any chopper pump. Continuously chopped solids not only eliminate nozzle clogging, but enhance sludge quality. Digester efficiency is increased by further reduci...

More Information » www.chopperpumps.com/products/rotamix/#overview

Triton® screw centrifugal pumps, combining the benefits of Vaughan’s superior pump designs with the advantages of high efficient, non-clogging performance. The Triton screw centrifugal pump’s open channel impeller is ideal for handling thick sludges, large or stringy solids, shear sensitive fluids and delicate or highly abrasive materials.

The Vaughan Conditioning Pump™ is a Vaughan Submersible Chopper Pump mounted on a portable stand and fitted with high-velocity mixing nozzle. The Conditioning Pump recirculates the contents of the wet well, chopping and mixing to produce a homogeneous mixture that is more easily pumped out. Floating mats are removed and solids that have accumulated on the floor are re-suspended. As the pump is mounted on a portable stand it can easily be used in multiple applications at a single job-site, facility or municipality. Another high quality offering from the brand you trust.

The Vaughan Company offers a series of portable bypass pump package options that can be used for tough solids reduction applications or low shear solids handling in temporary or permanent situations. Our pumps are on a trailer or skid mounted platform powered by either diesel, hydraulic or electric drive motors.

Vaughan’s Turbo-S Mixer is a propeller mixer mounted vertically inside an 18” elbow. This mixer has replaced many submersible propeller mixers which have experienced motor or gearbox failure due to fluid inleakage. The Turbo-S can mix a pit with just approximately two feet of liquid above the floor, something a horizontal shaft submersible mixer cannot do.

The Turbo-S also incorporates Vaughan’s upper cutter above the propeller to stop wrapping and fibrous material binding and to protect the mechanical seal. The Turbo-S has been used extensively in dairy manure mixing but also in municipal treatment plant anoxic zone mixing and in oxidation ditches. An optional add-on turntable can allow the Turbo-S to be easily re-aimed in the pit.

The patented Foambuster uses the same glass-lined ductile iron nozzles as Rotamix but also uses a stainless steel splashplate located below the nozzle to deflect the nozzle discharge and create a broad spray of sludge, which wets and breaks up foam forming on the surface of the digester. Digester sludge is pumped through the Foambuster either by the Rotamix Chopper Pump or by a separate Chopper Pump. When the Foambuster is used in conjunction with a tank mixing system, which produces a rotational mixing pattern in the tank, only one spray nozzle will be required for effective foam control.

Small tank mixing is a lower cost, simplified Rotamix system, using a Chopper Pump and external-mount nozzle assemblies. The external-mount nozzles are sandwiched between 6" ANSI flanges and provide fixed discharge angles off the tank wall. The nozzles can be made of light-weight 316SS or SCH40 steel with glass lining. These systems are ideal for FOG mixing (fats, oils, & grease) or for small food waste tanks which often use light weight fiberglass tanks.

The nozzles in this system also can be manipulated to create low or high turbulent conditions that are ideal for mixing additives or separating solids in the chemical processing and oil and gas industries.

Consider a Vaughan Applications Pump for any of these applications: Lift station conditioning; Basin conditioning; Influent station/channel conditioning; Holding tank conditioning; Digester cleanout/homogenization. More »

Vaughan Pump stands strong through the wettest tropical storm in U.S. history. More »

49% overall improved efficiency with Vaughan Rotamix. More »

Complete the attached Pump Inquiry Form and return to info@chopperpumps.com. More »

Please complete the attached Rotamix Inquiry Form and return to info@chopperpumps.com More »